Sanitary wall as room dividers in dry-wall construction

Space gain: Sanitary walls as room dividers are usually installed between two bathrooms. The sanitary technology for both bathrooms is installed in this partition wall, as are the risers.

The big advantage is that you can save between 10 and 15 cm of installation space per bathroom. Depending on the number of bathrooms, this can even create an additional room in a hotel.

Room partition walls must of course meet sound and fire protection requirements. In order to be able to assume responsibility here with tested components, we offer this variant of the sanitary wall exclusively as a design that is piped by us in the factory in combination with blow-in insulation.

Sanitary wall as a pre-wall in front of a solid or dry wall

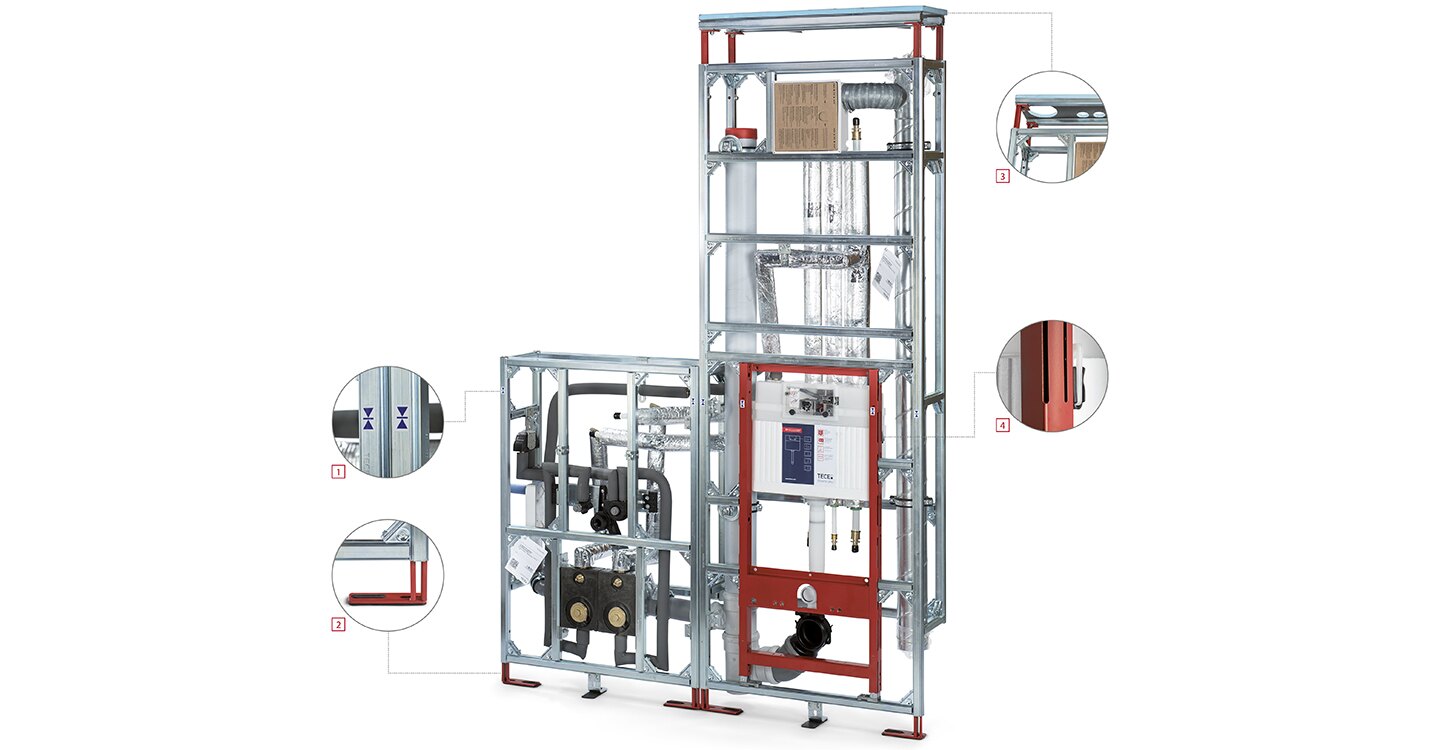

Whether as a mid-high sanitary wall with toilet and washstand module, or with a shaft, as a floor-to-ceiling pre-wall or in a T-shape for room partitioning: TECEsystem offers many possibilities. The degree of prefabrication ranges from an unpiped supporting structure with sanitary modules to a fully equipped system wall with all pipes, insulation, fresh water station or underfloor heating distributor.

Advantages in detail

You can tell if a system is well planned by whether the details are right

TECE has been active in system construction for over 20 years. Every day, our experts are out and about on building sites, talking to fitters, architects and planners. Our customers tell us about their experiences with the system walls and always have good ideas for improvements in detail. We implement these wishes in our product development. After all, satisfied customers who enjoy working with TECEsystem are the basis for our success.

1 Metre tear

TECEsystem sanitary walls are produced to a metre tear. This means segments can be easily arranged and adjusted at the assembly site.

2 Register feet

The prefabricated sanitary wall can be assembled by one person. The practical telescopic feet with a height adjustment of up to 25 cm help with this. The feet also provide sufficient mounting freedom for the waste water piping.

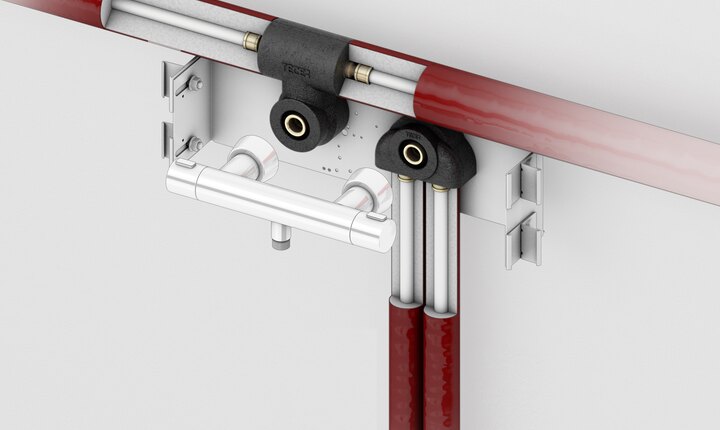

Potable water hygiene

Due to the high hygienic standard of drinking water as a foodstuff on the basis of the Drinking Water Ordinance, high demands are placed on the planning, installation and operation of drinking water systems.

With high-quality and coordinated TECEsystem components (e.g. the TECEprofil toilet module with integrated hygiene flush or the TECE hygiene box), TECE fulfils the relevant standards and regulations for drinking water quality. The TECE project team helps here with system selection and offers technical planning support.

3 Lost formwork

The lost formwork ensures safe backfilling of the slab openings. The sound and fire protection regulations are complied with. The telescopic ceiling connection offers an installation clearance of 15 cm.

4 Sound insulation

All components are soundproofed. Bolted components can thus still be adjusted on site.

Blow-in insulation technology

The TECE system solution with mechanical blow-in insulation technology, which spans all trades and interfaces, combines the requirements of fire protection, sound insulation and drinking water hygiene into a factory-prefabricated functional component. In this way, we can significantly reduce the risk of construction defects, simplify acceptance by the building authorities and optimise the entire construction process of your project.

In the best case, we can use blow-in insulation to make room partition walls thinner than usual and thus save installation space. In a hotel with 20 rooms per corridor, this can result in space for an additional room!