New drain valve A2-2019

Continuous advancement

With the continuous advancement of flushing technology, TECE has been following trends and changing market requirements from the start. With the addition of the drain valve A2-2019 for the TECE cistern, we're currently adding two updates to the series production.

Optimisation for ceramics with increased flow resistance

When the first rimless ceramics hit the market, they often tended to overspray because the flushing technology at the time was designed for powerful rinsing of the rim. TECE subsequently brought a multi-component throttle set to the market that lets you adjust the flushing pressure. Today, many toilet ceramics are already constructed with hydraulic resistance that is intended to prevent overspray. Yet the resistance is so high in some models that the drainage of the flush water from the tank and thus also the hydrodynamics of the drain valve can be negatively impacted. TECE has therefore adjusted the operation point in the operating range of the drain valve A2-2019 to also accommodate the higher hydraulic resistances of some ceramics.

In an endurance test it was found that the impact of the respective flow resistances was transferred to the drainage behaviour in a range of toilet ceramics. The result showed a broad variance, which had to be taken into consideration during further development of the drain valve A2-2019.

Improved resistance against dirtying

Depending on the lime content of the water, limescale can build up in the cistern over a longer operating period. Under unfavourable conditions, fragments of limescale or other dirt particles can work their way into the lifting zone of the drain valve. The resulting friction here impacts the balance between buoyancy and weight force, which can lead to deviations in the flush volume or continuous flush - and in the worse instance - to the valve getting jammed. This is why the new TECE drain valve A2-2019 has been equipped with a new dirt reservoir which keeps the lifting zone free of interference and ensures the flush works reliably with the desired volume.

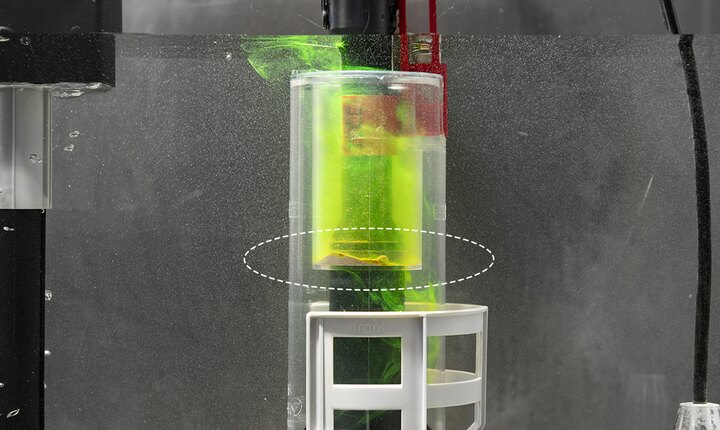

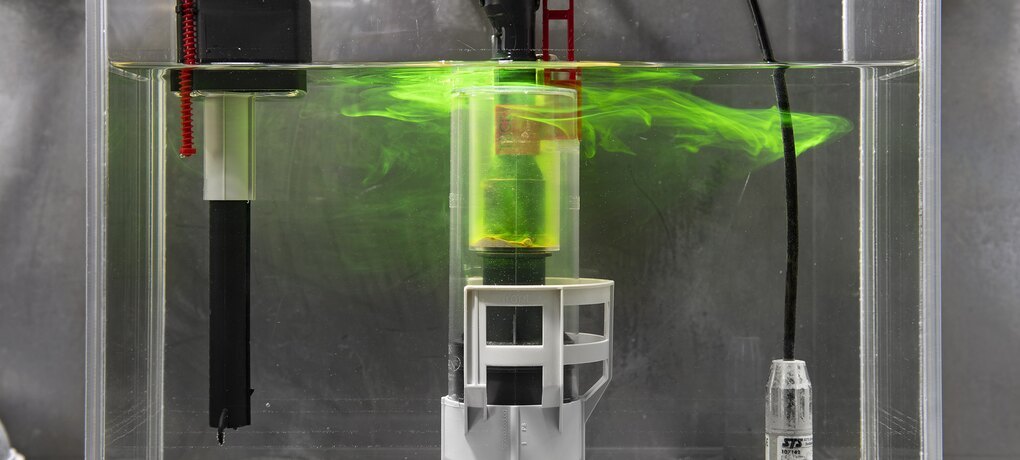

In a lab test, the lifting zone of the new drain valve is directly filled with dirt particles in different grain sizes. The respective flush volume is measured during the subsequent flushing intervals and the settling behaviour of the dirt particles is documented via camera.

Following the flushes, the dirt particles have settled in the newly developed dirt reservoir and the lifting zone is thus free of interferences.