Straightforwardness and pragmatism – the new weisenburger headquarters in Karlsruhe

When a construction company builds its own new headquarters, it has to be something special. The weisenburger company opted for a functional, understated yet confident building and engaged a renowned architect: The design was the work of Japanese Pritzker Prize winner Tadao Ando. "A shared concern of the architect and client was to create an aesthetically pleasing building that meets the latest technical standards, is energy-efficient, and offers our employees the best working conditions," explains Nicolai Weisenburger. The result is a staggered building with a seven-storey cantilevered head section and four-storey side wings made of exposed concrete. It is crowned with a spacious, green roof terrace.

Aesthetics of concentration

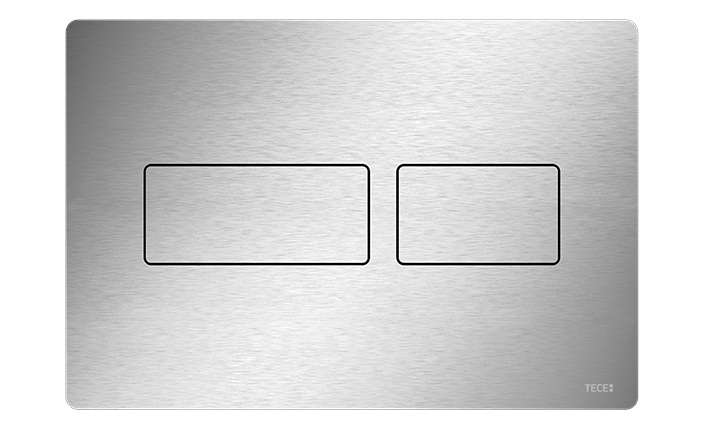

The "master of minimalism" uses exposed concrete according to his "own recipe." With smooth surfaces and sharp edges, the velvety feel typical of Ando lends the building a sense of elegance and rigor. The material and color palette is simple and elegant; Ando masters the art of reduction, not only in the facade but also in the spatial experience – down to the last detail. For the bathroom area, the designers opted for flush plates from the TECEsolid series, which, with their visual quality and robustness, are particularly attractive for semi-public areas. The flat design, harmoniously rounded edges, and high-quality stainless steel surfaces create a visual elegance that integrates perfectly with Ando's overall concept.

State-of-the-art technology

The new corporate headquarters is not connected to any external heat sources. The required thermal energy is generated via heat pumps using a predictive control strategy. To store the energy, the floor slab of the third basement level and the ceiling of the first basement level are activated to form a thermal buffer storage system. The heat and cold are transferred to the room completely autonomously via two parallel, independent systems. This saves 30 tons of CO2 per year.

The building contractor knows that, especially in bathrooms where space is limited, coordination between trades is essential. With the TECEprofil pre-wall system used, toilets, washbasins, and other sanitary elements can be installed safely and individually in the bathroom using drywall construction – regardless of the factors that typically dictate their placement. The pre-wall technology makes it possible to implement various room layouts and easily and reliably comply with standards and regulations. This gives the building a coherent signature, from its overall appearance down to the last detail.

the flush plates of the TECEsolid series fit seamlessly into the bathroom.