Potable water hygiene starts before the planning stage

Hygienically perfect potable water can only be ensured over the entire life cycle of the building if the right course is set during the construction phase. Everyone involved in the construction should therefore know at least the basics of what needs to be taken into account when it comes to planning and implementing a flawless potable water installation. This article provides an overview and a look into the tool kit of an expert.

Potable water hygiene begins even before the actual planning process, as Arnd Bürschgens, publicly appointed and sworn expert for potable water hygiene in the plumbing and heating installation trade, (www.wfw-twh.de), points out. What is meant is the room book, in which the architect and the client determine the requirements to be placed on the building. In addition to the equipment and electrical systems, potable water extraction points and wastewater installations are specified according to the occupancy and type of use of each room. Designs on this basis are always superior to standard and average values.

Technical requirements are uniformly regulated at EU level in accordance with the DIN EN 806 series of standards in conjunction with the national DIN 1988 series of standards “Technical rules for potable water installations”. Regulations such as the VDI guideline series 6023 “Hygiene in potable water installations” or the DVGW worksheet W 551, which is primarily aimed at reducing the growth of legionella, go into a little more detail. However, according to Bürschgens, the complex sets of rules can be broken down into easily understandable requirements.

Cold water has to stay cold

In order to slow down the growth of micro-organisms that always remain in the water and multiply at extremely high rates, especially in temperature ranges from 25 to 50°C, the cold water temperature should remain below 25°C. If higher temperatures are to be expected in the area, the cold water pipe must be insulated or physically separated from warm pipes. An example of this would be a parallel hot water line in a sanitary wall. Since even the best insulation can only delay a rise in temperature, time also plays a role, which leads directly to the requirement that stagnation in the potable water installation must be prevented. According to Bürschgens, this requires a complete exchange at least every three days. You can systematically work towards this goal in planning: the number of tapping points and the volume of the installation itself should be minimised, which helps to ensure the water exchange in everyday use.

The limiting factors here are pressure losses, which are more significant with small diameters. For complete flushing, the lines should be looped through using U-wall disks and at the end there should be an object that is used regularly, for example a toilet. A further measure could be a flushing device, the type which is often offered by the industry today. A flush valve with programmable control is set at the end of the looped line. With these devices, as Bürschgens goes on to explain, care should be taken that there are no more than two dimensional steps in the pipeline, otherwise the opening times of the flushing valve would be too long. Nevertheless, even with systems optimised in this way, small amounts of residual water remain in the short pipelines or the reinforced hoses between the U-wall disk and the valve. This means that the user remains responsible for using the tapping points on a regular basis.

Keeping warm water in circulation

There is also a requirement for temperature maintenance for warm potable water. Here the temperature must not fall below 55°C, also to limit the growth of micro-organisms. DVGW worksheet W551 sets out the 3 litre rule, according to which after opening the hot water valve and a flow rate of three litres the temperature must be at least 55°C. In small systems, this can be achieved via a short pipe to the heat generator or to the hot water storage tank; in larger systems (> 3 litres), circulation is required.

Deviating from this, the EU standard requires the hot water fitting to open for 30 seconds before this temperature is reached. Since the time depends on the volume flow through the tapping valve and can therefore not be clearly determined, this requirement can be at most a general guide value for hot water convenience. The 3 litre rule is therefore a relevant regulation in Germany.

Who is liable for faults?

In the German legal system, the person who caused a fault is liable – in the case of improper planning, primarily the planner. However, this can lead to disputes because the installer, as the company carrying out the work, is also experienced and should, to a certain extent, be aware of inadequate planning and flag any concerns.

However, the most common cause of disputes that land on Arnd Bürschgens' desk – he indicates around 70 percent, relates to incorrect operation for which the operator is liable. In this case, liability can rest with the installer if the operator, as a layperson, has not received any instruction. Good acceptance and documentation procedures are therefore essential. VDI 6023 provides forms for this where the operator can confirm having received instruction. If the property is rented out, the tenant is next to be instructed as the last link in terms of intended use. There is also a sample sheet for this in the new VDI 6023 Part 3. The prerequisite for the tenant to be held liable is, of course, a contractually compatible potable water installation that is also regularly maintained.

Practical experience for commissioning

In the time between installation of the system and its commissioning, mistakes can be made which can lead to extremely costly consequential damage. Bürschgens recommends an initial hygiene inspection in accordance with VDI 6023 as the first step after construction. For this purpose, the client or the client’s representative commissions an expert who checks before the initial filling whether the installation complies with the planning and the technical regulations. If a fault is found, it can usually be remedied with little effort because the building project is still in the shell construction phase.

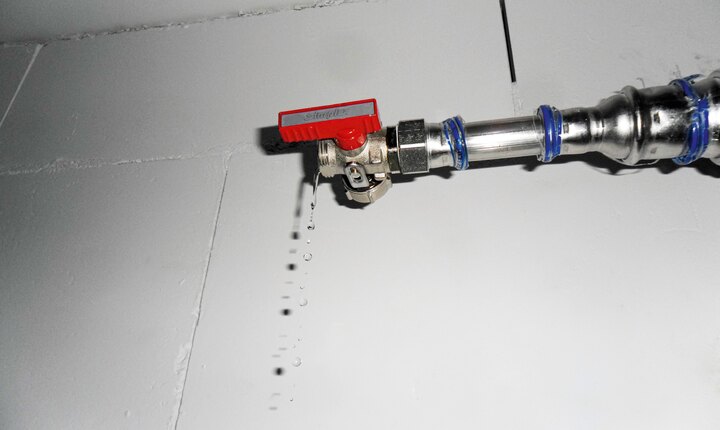

The next step is the pressure test with dry, oil-free compressed air or with inert gases. Pressure tests with water, which often lead to costly consequential damage, are still widespread. Arnd Bürschgens tells of two actual cases: in a larger potable water installation in a barracks, the water from the pressure test remained in the pipe for four months over the summer. Afterwards, massive contamination with fecal-based micro-organisms (E-Coli) and pseudomonas was found at each extraction point. Efforts to eliminate the contamination through flushing, disinfection and continuous potable water disinfection have been ongoing for over two years – with corresponding amount of loss. In the second case, an apartment building, although the installer emptied the system after the pressure test with water, a potable water installation cannot be completely emptied because water always remains in the undercuts and annular gaps in press fittings. A high degree of contamination with pseudomonas was also found.

The next cliff to be avoided is the initial filling of the installation for flushing during commissioning. The domestic water connection is the critical point here, because in the construction phase it is often hardly used or not used at all for longer periods, leading to stagnation. The domestic water connection should therefore be rinsed thoroughly and tested so that the brand new potable water installation is not spoiled with contaminated water. If the domestic water connection is OK, the first sampling should be carried out at representative sampling points after filling and flushing. The parameters according to the Drinking Water Ordinance, E-Coli and Coliforms must be checked.

This provides proof of acceptance that the potable water installation is in a perfectly hygienic condition. If there is still time between filling and acceptance, the installation remains the property of the installer for this period and the installer must ensure that the system is operated as intended – or carry out the initial filling immediately prior to acceptance. If the operator adheres to flushing schedules and deadlines for maintenance and repair from now on, the potable water installation will in all likelihood deliver high quality and hygienically perfect potable water over its service life.