More efficiency in the construction process

The advantages of TECEsystem, i.e. industrially prefabricated installation walls and shafts, for large construction and renovation projects are well known: They ensure continuous construction progress right from the start, minimise the coordination effort and simplify work on the construction site. Where plumbers and drywallers would otherwise assemble installation walls and shafts from many individual parts in cramped bathrooms, the right assemblies are delivered to the construction site at the right time, completely prefabricated. They usually contain the entire pipework for all media, the shut-off devices, the preparation for accommodating water meters and fan boxes as well as the formwork for the ceiling bulkheads. On site, the TECEsystem installation walls and shafts are simply aligned and fixed to the building structure. Then only the pipework needs to be connected together. This significantly reduces the installation time on site, as well as the coordination effort between different trades. In addition, there is no need for constant administration, procurement and collecting of the many individual parts on the construction site. Downtimes are demonstrably reduced.

With prefabrication, both new build and refurbishment projects can be planned with time windows that are almost impossible to realise using conventional construction methods. This means that investors and the housing industry benefit from a faster ROI (return on investment). During refurbishment, loss of income is reduced or avoided altogether; in the case of refurbishment in an occupied state, the costs of external accommodation for residents are also reduced.

In addition to the economic benefits of serial prefabrication, there is also the benefit in terms of building law. Once a building has been completed, planners and contractors are liable for its safety, the technically correct implementation of all measures and the faultless functioning of all components. With prefabricated installation walls, TGA planners and installers reduce warranty claims and at the same time ensure the cost-effectiveness of their calculations. This is because risks can be outsourced from the planner's own area of responsibility following standard-compliant planning. We assume the warranty for all products and pipe connections installed in the prefabricated installation walls and thus support you not only with the installation on site, but also with the reliable implementation of the building code requirements.

Workshop prefabrication - less stress for everyone

In principle, many of the above-mentioned advantages can be transferred 1:1 to workshop prefabrication with TECEprofil pre-wall elements. Here too, it is above all the simplification of the process sequences that speaks in favour of preparing the installation walls in the installation company. Old bathrooms in particular are often very small or angled. The plumber is forced to work in a very confined space. In addition to the obvious restriction of freedom of movement, there are also delays due to unnecessary travelling times if materials and tools cannot be stored directly at the installation site due to lack of space. In the worst case, missing or forgotten equipment has to be procured later. In the workshop at the company, on the other hand, the spatial conditions are generally much better. This makes installation easier, faster and also less stressful.

If you would like to realise a project as cost-effectively and reliably as possible, please contact us! We will be happy to advise you!

Another major advantage is the improved service provided to customers. Just as with industrial prefabrication, the installation walls and shafts only need to be aligned, fixed and connected on site, which reduces the actual working time on the construction site many times over. This means that clients are much more flexible when it comes to coordinating the various trades.

In addition, there is no more frequent running back and forth between the material and the installation site. The tradesmen bring the pre-wall elements that have already been installed into the bathroom once, install them there and leave the construction site again. The residents will appreciate the considerably reduced noise and dirt nuisance, especially when the renovation is carried out while the building is occupied.

TECEsmartwall - the tool for the prefabrication of installation walls

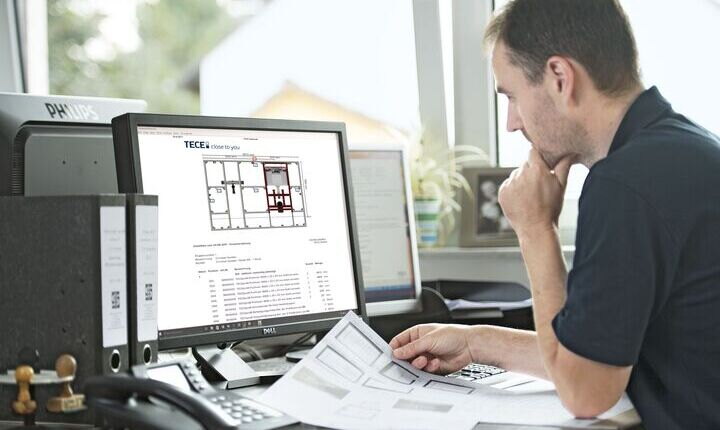

With TECEsmartwall, we provide you with a convenient tool for the virtual planning of installation walls. The software is simple and intuitive to use. In just a few steps, you can create dimensioned wall sketches, as well as tender documents, quotations, detailed lists and precise calculations.

For the greatest possible freedom in bathroom design, TECEsmartwall offers a wide selection of different wall types such as room-height, part-height, with a sloping roof and fixed on one or two sides. The configurator always contains all TECEprofil products from the current range list, including special solutions such as the narrow TECEprofil WC module with Compact 320 cistern or the low TECEprofil WC module with Uni 750 cistern. The easy-to-use online tool can be used to plan the perfect bathroom for any floor plan - whether for new builds or renovations.

There is now a new user profile especially for tradespeople who use TECEsmartwall for the configuration of TECEprofil installation walls for prefabrication in their own company. This offers users helpful additional functions such as the reduction of the supporting structure dimensions in order to be able to compensate for construction tolerances later on.

Prefabrication - more than worth considering!

Whether on a large or small scale, the prefabrication of installation walls and shafts has no disadvantages, but many advantages. Even wholesalers have already recognised this and are offering space to installers who do not have sufficiently large premises. This has the added bonus that the trade can deliver all the required materials just-in-time for processing.