Shaping tomorrow amidst historic walls

At the Opladen site, a modern residential space for students has taken shape at the very heart of the complex.

The historic exterior walls bear witness to the site’s long industrial heritage, while the modern interior propels the new urban quarter, Cube Factory 577, into the future. On the grounds of the former railway repair works in Leverkusen-Opladen, new life has been brought to the area under the direction of project developer Cube Real Estate. At its centre: attractive new living space in the form of 302 student apartments.

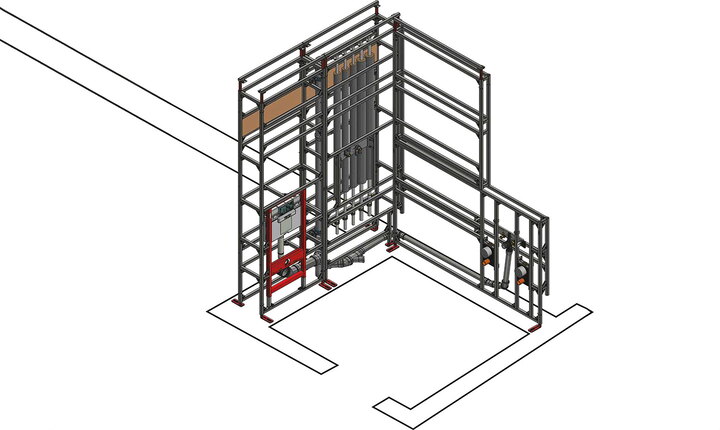

When planning and constructing the sanitary units, the project developer relied on serially prefabricated installation walls from TECEsystem, significantly increasing construction efficiency compared to conventional building methods. “Modular construction should be examined and planned as early as the initial development stage, meaning during service phases 2 and 3,” explains Behnam Afshar, who – together with Jens Hedtke – coordinates the development of the new district for Cube Real Estate GmbH.

Industrial prefabrication firmly established in construction

“Due to the large number of micro-apartments and the resulting similarity of bathroom types, modular construction with serial prefabrication could be implemented in the bathroom areas. In addition to the consistently high execution quality, the short installation times proved particularly advantageous — not least because the modules are stacked on top of each other, allowing for simple pipe installation within the shafts,” explains Jens Hedtke.

“It is important to consider the corresponding implementation measures early in the planning process so that the construction method is taken into account before tendering — otherwise, interface issues may arise on the construction site. If this is achieved, modular building units can shorten construction time and reduce on-site errors,” says Behnam Afshar. “With regard to modular construction, it is crucial to discuss interfaces with the individual trades at an early stage. Preliminary work must be completed at the latest by the time the modules are delivered to the site, in order to avoid hindering the construction process.”

The new student residence is arranged around an open courtyard, forming a four-storey rectangle with eight different apartment types to choose from. Behind the walls lies high-quality technology: in the approximately 302 apartments, just as many industrially prefabricated installation walls from TECEsystem have been installed. The load-bearing structure, supply lines, WC, washbasin and shower modules, as well as insulation, fire protection and soundproofing are all delivered to the construction site just-in-time as a complete prefabricated assembly.

© Matthias Ibeler

In most cases, full-height installation walls were used, to which the kitchen unit of each apartment was connected from the rear. Integrated laminated timber panels within the installation walls ensure secure mounting for the wall cabinets.

Fire and sound insulation included

In this project, the decision-makers opted for ceiling-penetration fire protection. To ensure precise and safe implementation of the firestops, the installation walls were delivered with accurately fitting, lost formwork elements. Before the penetrations are filled, the corresponding pipe firestops are placed into these recesses and clearly marked. TECEsystem installation walls meet all legal requirements regarding sound and fire protection. They are fundamentally constructed using the TECEprofil supporting framework, which is officially approved by the German Institute for Construction Technology (DIBt) for the creation of non-loadbearing fire protection structures and is supplied with the corresponding Ü-certification Z19.140-2573.

In addition, the installation walls comply with the legal requirements of DIN 4109-1 as well as the enhanced requirements of DIN 4109-5. TECE provides full warranty for this.

LEED v4 certification

The office spaces completed in the first construction phase are already LEED v4 certified. Factors influencing LEED (Leadership in Energy and Environmental Design) certification include criteria such as location, transportation, sustainable site development, and innovation. The system is used internationally and defines standards for sustainable construction. In the future, the entire site is intended to comply with this globally recognised standard for environmentally friendly and resource-efficient building.