"The pipe for all application"

Competence: Installation & Assembly

TECEflex: The universally application classic

The robust fitting classic TECEflex has guaranteed exceptionally secure pipe connections for more than 20 years. TECEflex functions on the principle of the axial press technique: The pipe is expanded, pushed over the fitting and reliably secured with a pressure sleeve.

- O-ring free connection technology.

- Error-tolerant and secure.

- Suitable for drinking water, heating, gas and compressed air installations.

- Pipe and fitting with approximately equal inner Diameter.

A robust coat of aluminium protects it from knocks and impacts: The inner pipe is particularly strong and keeps the pipe's shape even under heavy pressure. Nevertheless, it's still easy to bend by Hand.

"The pipe for every situation"

Friedrich Justus GmbH is located in Grasberg in Lower Saxony and this is celebrating 60 years as a company. Quality and dedication to the values of craftsmanship are as responsible for the company's lengthy existence as well as a satisfied customer base. Making sure nothing leaks after an installation is the fundamental requirement for customer satisfaction. Steffen Biehl, sanitation, heating and air-conditioning boss at Justus GmbH, tells of his experiences with TECEflex.

TECElogo: Literal craftsmanship

Installing pipes without high-maintenance pressing tools? TECElogo makes it possible. The professional push-fit system is quick and simple to operate by hand. Cut to length, calibrate, push-fit – done. Pipe cutter, calibration pin and bare hands are enough for a durable, secure Connection.

- Fast and simple assembly.

- Comfortable working in tight, hard to reach places.

- Overhead work is made significantly easier.

- Wrong connections are easily solved and pipe and fitting can both be used again afterwards.

"Push-fit has convinced me"

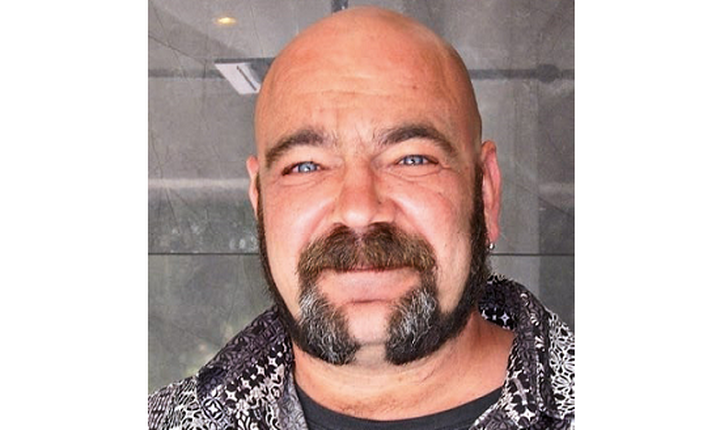

Sanitation, heating and air-conditioning master Kay-Uwe Baak from Berne in Lower Saxony employs up to five staff depending on the season. A trade company of this size especially can't afford to make any mistakes on installation. TECElogo met every single one of the entrepreneur's expectations.

Mr Biehl, what convinces you about TECEflex?

The sliding sleeve system is easy to operate and the connections can be made with a hand tool up to dimension 32 millimetres. We use exclusively TECEflex red brass fittings and are very satisfied with the quality – there has never been a problem yet. We've been using this system for around six years now.

Do you also use any other pipe systems?

Hardly. We still use copper but only for repairing existing systems. Otherwise we only use TECEflex. For all kinds of installations: Heating, gas and drinking water, both in new builds as well as renovations of old properties.

How much training effort do your fitters need before they've mastered the system?

It's no big deal to learn. Demonstration is so easy: After colleagues have seen how it functions once, nothing can really go wrong. Sometimes when the TECEflex salesperson responsible for us is on site, he takes advantage of the situation and explains to the trainees very painstakingly how to work with TECEflex. But all in all, the system is self-explanatory. And that's a good thing.

Mr Baak, how long have you been working with TECElogo and where do you use it?

I've actually been using it since it came to market, one of the very first customers so to speak. I've been freelance for 20 years. I tried out four other pipe systems before TECElogo, none of which convinced when it came to handling. I use TECElogo for heating and drinking water installations in new builds, but most of the time for renovating old buildings.

Which advantages do you think the system has?

The great flexibility. Thanks to the removable connection, it's no tragedy if an installation error occurs. The push-fit connection is easily undoable and I can then reuse the fitting. This not only minimises the resulting waste but my costs as well. Aside from that, I'm not reliant on heavy pressing tools. It makes overhead work easier and I don't constantly have to keep charging any batteries. An advantage that is very noticeable also when assembling in tight spaces.

How much training effort do your employees need before they've mastered the system?

There's actually no need to mention effort. Show it to them once and they understand the system. Even my apprentices in the first year "can do" TECElogo.