Core renovation with a lightweight solution

TECEfloor underfloor heating in dry construction enables conversion of historic old building

Ingelheim am Rhein is developing the ‘Heidesheimer Höfe’ construction site and has chosen TECE for the project. A new neighbourhood is being built there on an area of around 5.2 hectares. At its heart are Haus Rheinblick and Haus am Park. The two former residential homes of the Evangelisches Diakoniewerk Zoar are part of the historic section of the overall complex and are listed buildings. They are being completely renovated and converted into flats.

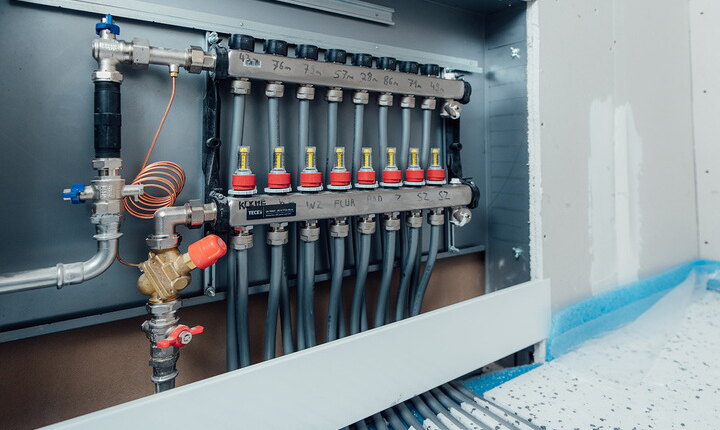

The planning office opted for the TECEfloor dry construction system to provide future residents with the comfort of underfloor heating.

This proven surface heating and cooling system makes it possible to install energy-efficient underfloor heating systems even in renovations such as this one. ‘The TECEfloor dry construction system makes it possible to renovate historic buildings in such a way that they are also compatible with modern heating systems such as heat pumps,’ explains Rainer Wendling, the TECE sales representative responsible for the construction project. "The architect wanted to preserve the building. The planning office supported the architect in this. Our goal was to create an energy-efficient building with affordable rents."

Each building will contain 18 residential units. The existing attic space has been partially converted for residential purposes. This has created an exceptionally large living area of 1,500 square metres, on which the TECEfloor TP 30 dry construction system has been installed. "A particular challenge when renovating historic buildings is often the statics or ceiling load. While a wet construction system with screed would put a strain on the statics due to its relatively high weight, the dry system weighs significantly less,‘ explains Rainer Wendling.

The dry system also offers other advantages: there is no drying phase as with screed. ’The tradesmen can continue working immediately. In addition, there are no moisture loads that can cause damage," he explains.

First, a level surface is created on the subfloor using bound levelling fill. Then, 30-millimetre-thick EPS carrier plates with heat conduction sheets are laid on top, with the aluminium composite pipes running in their grooves. This creates an efficient surface heating system with a surface load that is approx. 100 kg/m² lower and an installation height that is almost 4 cm lower – an advantage in renovations of old buildings with limited room height or lower doorways. The low installation height and storage mass allow the temperature to be easily adjusted: the surface heating system heats up and cools down quickly, and the heat is distributed evenly.

All TECEfloor components are coordinated with each other. The ‘Silver Line Quality’ (SLQ) seal of quality is the TECE quality standard for underfloor heating and ensures that all components for water-carrying and functional parts are coordinated with each other and that operability is guaranteed for all individual combinations. All SLQ-marked components of the TECEfloor system are subjected to thorough testing in the company's own test laboratory.

In addition, there is DIN-certified safety. This is because TECE participates in the ‘Certification programme for plastic pipe and composite pipe systems for hot water surface heating and radiator connections’ with TECEfloor. Pipes and fittings for underfloor heating are certified individually and as a system by the independent DIN-CERTCO Institute and are regularly monitored.